Multi-Part Handling CNC Automation

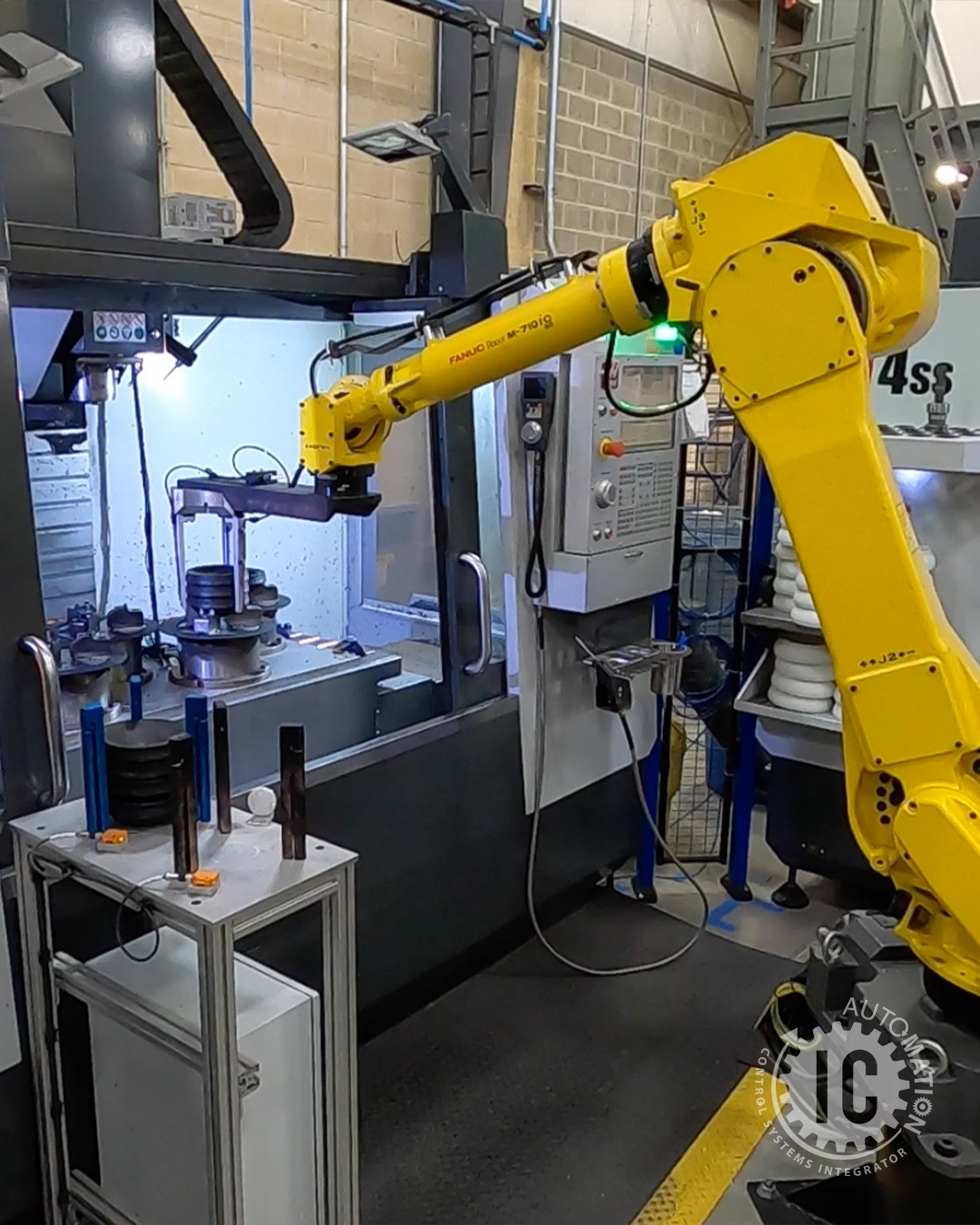

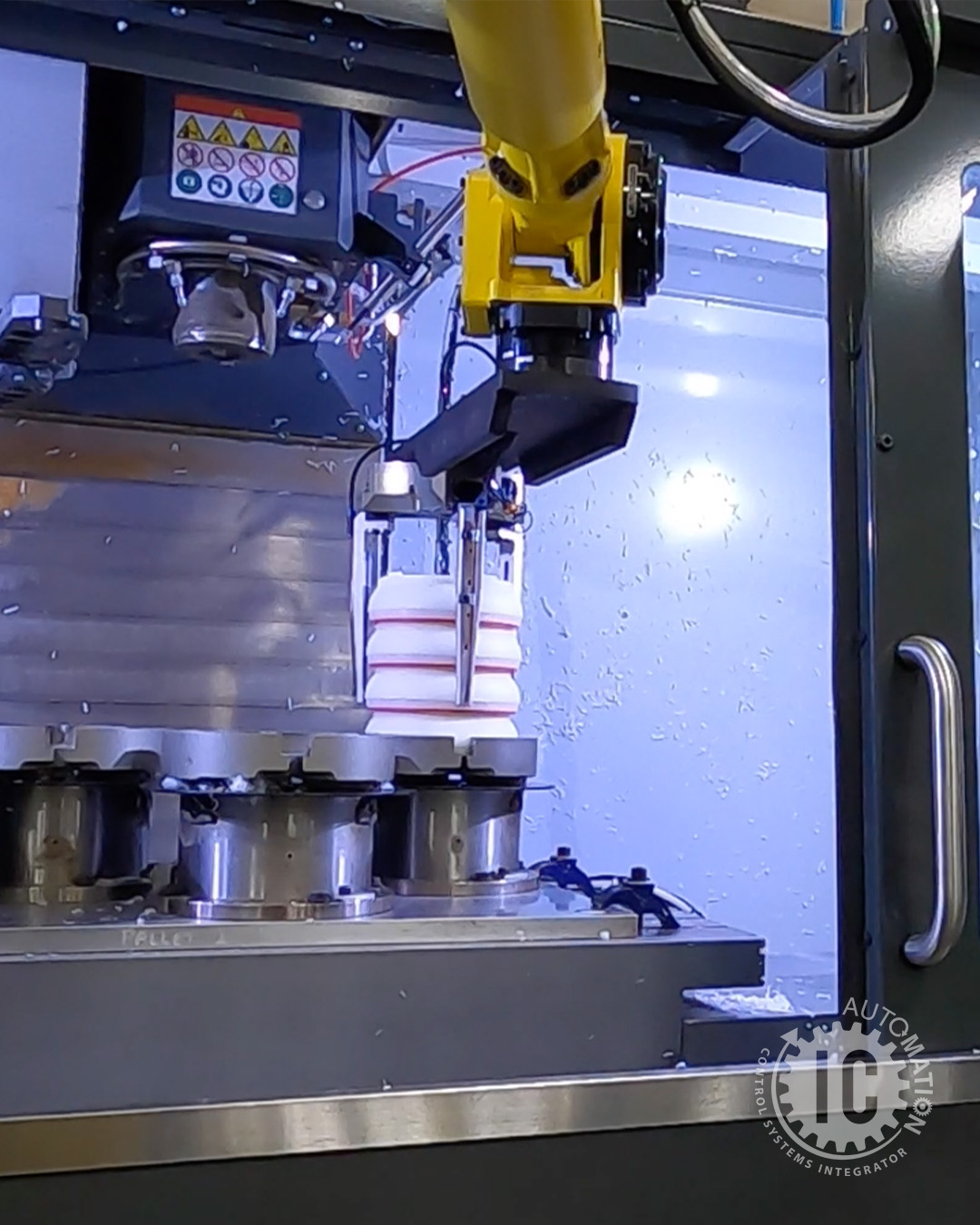

Our Multi Part Handling CNC Automation System was engineered to optimize complex CNC machining operations through intelligent robotic material handling. Designed to manage multiple part types within a single automated workflow, this system improves machine utilization while maintaining precision and repeatability across every cycle.

By integrating advanced robotics with CNC equipment, the system automates part loading, unloading, and transfer between machining operations. This approach reduces manual intervention, stabilizes cycle times, and allows CNC machines to run more consistently at peak efficiency. The automation is designed to handle varying part geometries and process requirements without sacrificing accuracy.

The system incorporates robust part tracking, precise positioning, and coordinated motion to ensure each component is processed correctly at every stage. Integrated safety features, custom fixturing, and intuitive operator controls support reliable operation in high volume manufacturing environments while allowing flexibility for future process changes.

Ideal for manufacturers seeking to increase CNC throughput and manage multiple part configurations efficiently, this automation solution delivers greater process control and scalability. It demonstrates IC Automation’s ability to design flexible CNC automation systems that adapt to evolving production demands while supporting long term manufacturing performance.

Looking to simplify or automate your manufacturing process?

Whether you’re just exploring options or ready to take the next step, our team is here to help. We make automation approachable and tailored to your needs. Reach out today and let’s start the conversation.

Address

6441 Davis Industrial Parkway

Solon, Ohio, 44139

United States

Phone