Featured Projects

Fully Automated Machining & Inspection Production Line

A complete machining and inspection line featuring robotics, vision systems, and multi-step part handling—automating everything from raw forgings to final packed components with precision and traceability.

Palletizing System

A high-speed robotic palletizing system built to handle mixed-size cases with precision. Featuring 3D vision and intelligent stacking, it delivers efficient, stable pallet loads without manual sorting—streamlining end-of-line operations.

Grinder Side Loading Cell

This side-loading automation system boosts OD and ID grinding efficiency with fast, consistent part loading. Its machine-independent design integrates easily into existing setups to reduce downtime and manual handling.

Clip Application System

Engineered for speed and accuracy, this system applies plastic or cardboard top clips to bottles with consistent precision—supporting multiple sizes and formats for high-volume packaging operations.

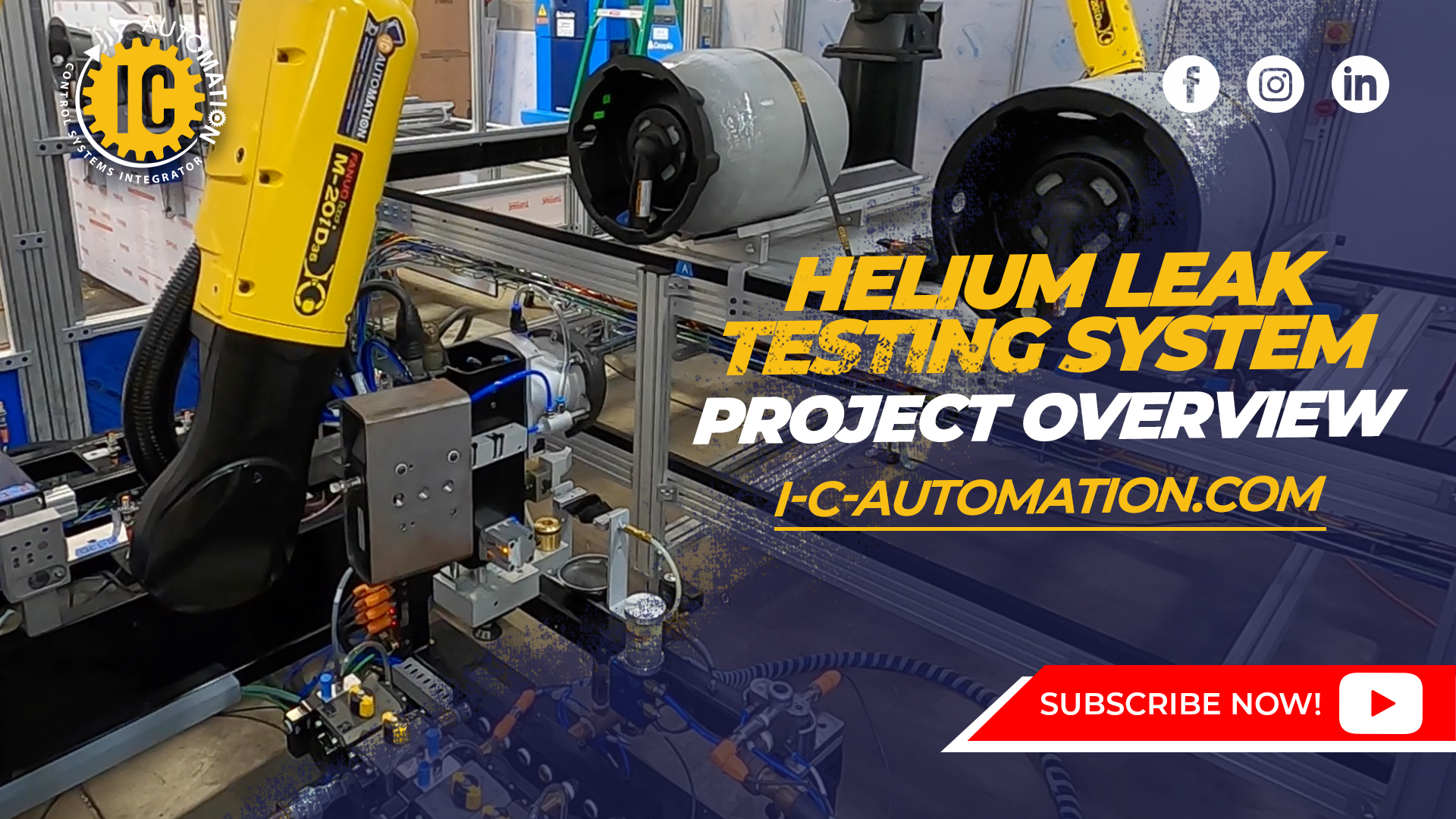

Helium Leak Testing System

A fully automated helium leak detection system using 3D vision and robotic tooling to inspect components under pressure. Eco-friendly, accurate, and ideal for high-volume, quality-critical applications.

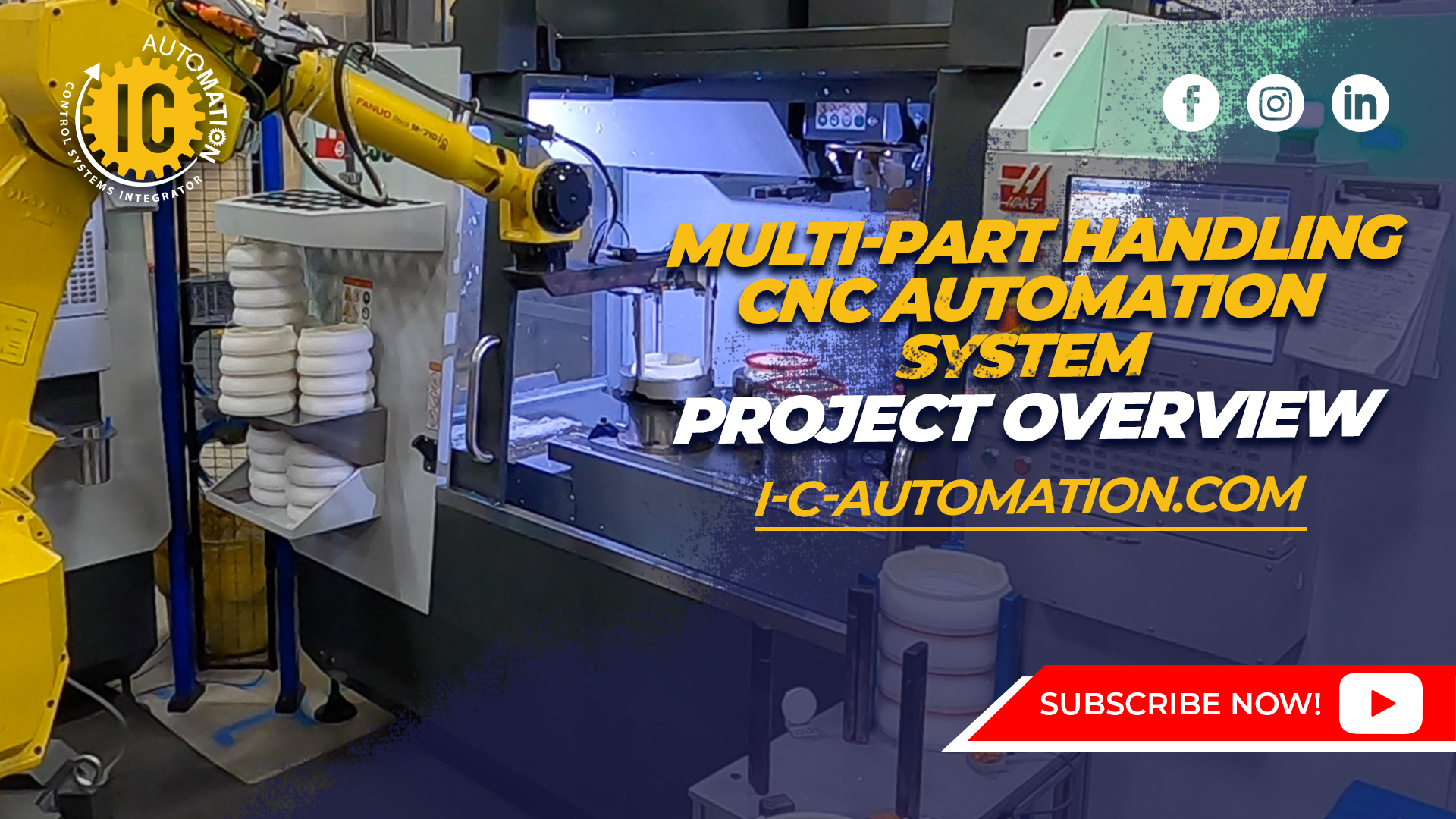

Multi-Part CNC Automation

A CNC automation solution capable of handling multiple part types across several machines. Includes smart part sorting, robotic tending, and efficient program control for flexible, high-throughput machining.

Address

6441 Davis Industrial Parkway

Solon, Ohio, 44139

United States

Phone