Automated Capacitor Former

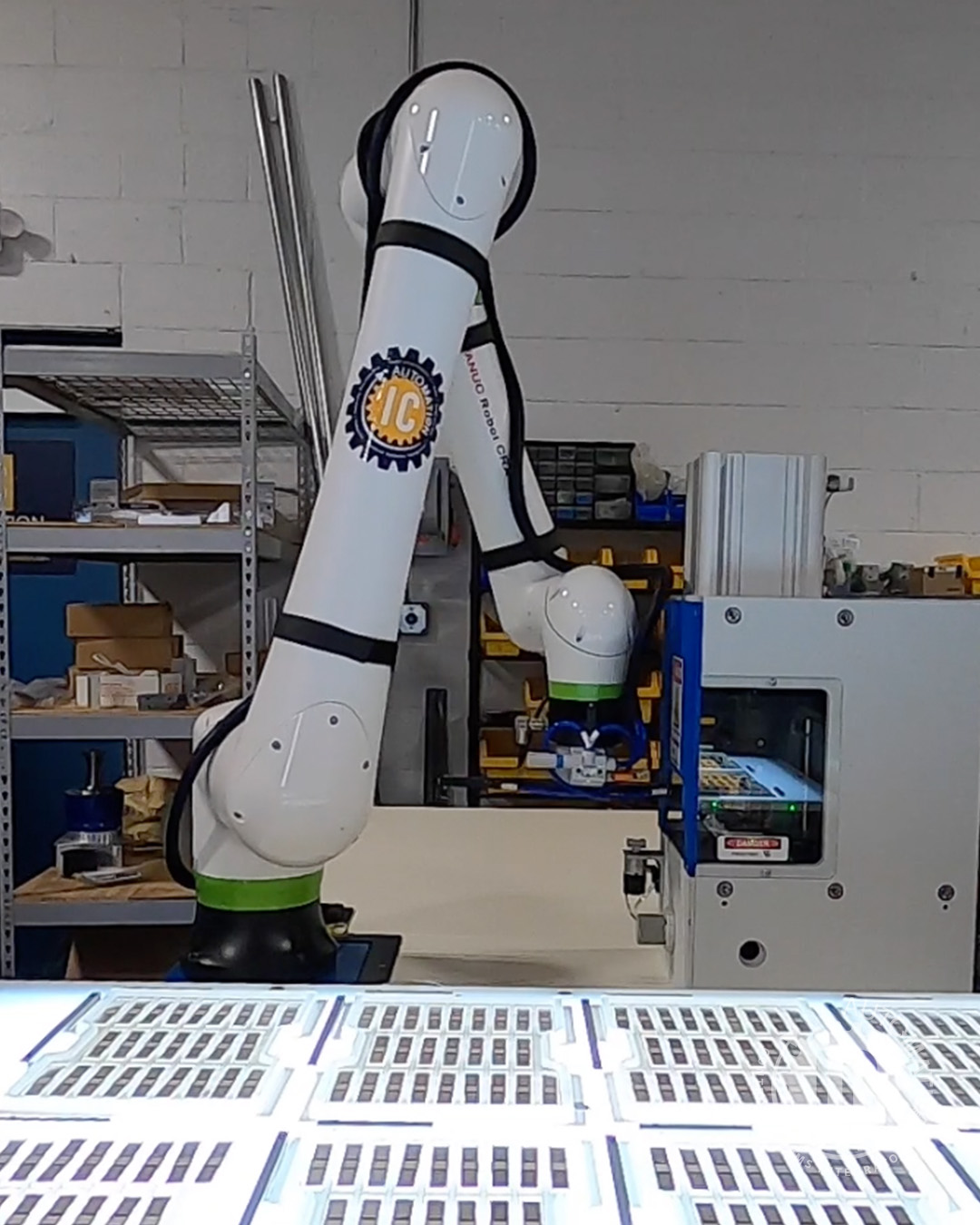

Our Automated Capacitor Former was developed to streamline and standardize critical steps in capacitor manufacturing through precise robotic automation. Utilizing a FANUC robotic arm, this system manages the complete forming process, including part handling, stamping, preparation, and inspection, ensuring accuracy and consistency at every stage.

By automating tasks that are traditionally manual and sensitive to variation, the system significantly improves efficiency while reducing the potential for errors. The robotic process ensures consistent positioning, controlled force during stamping, and reliable handling of delicate components. Integrated quality checks verify that each capacitor meets process requirements before moving to the next stage of production.

The automation cell is designed for reliable operation in high volume manufacturing environments. Custom tooling, integrated safety features, and intuitive operator controls support smooth operation while maintaining flexibility for different capacitor types and production requirements. The system can be integrated seamlessly into existing workflows, helping manufacturers modernize their processes without disruption.

Well suited for manufacturers seeking greater process control and repeatable quality in capacitor production, this automated former delivers measurable improvements in consistency and throughput. It demonstrates IC Automation’s ability to apply robotics to precision manufacturing challenges, providing a dependable solution that supports long term production goals and evolving product demands.

Looking to simplify or automate your manufacturing process?

Whether you’re just exploring options or ready to take the next step, our team is here to help. We make automation approachable and tailored to your needs. Reach out today and let’s start the conversation.

Address

6441 Davis Industrial Parkway

Solon, Ohio, 44139

United States

Phone