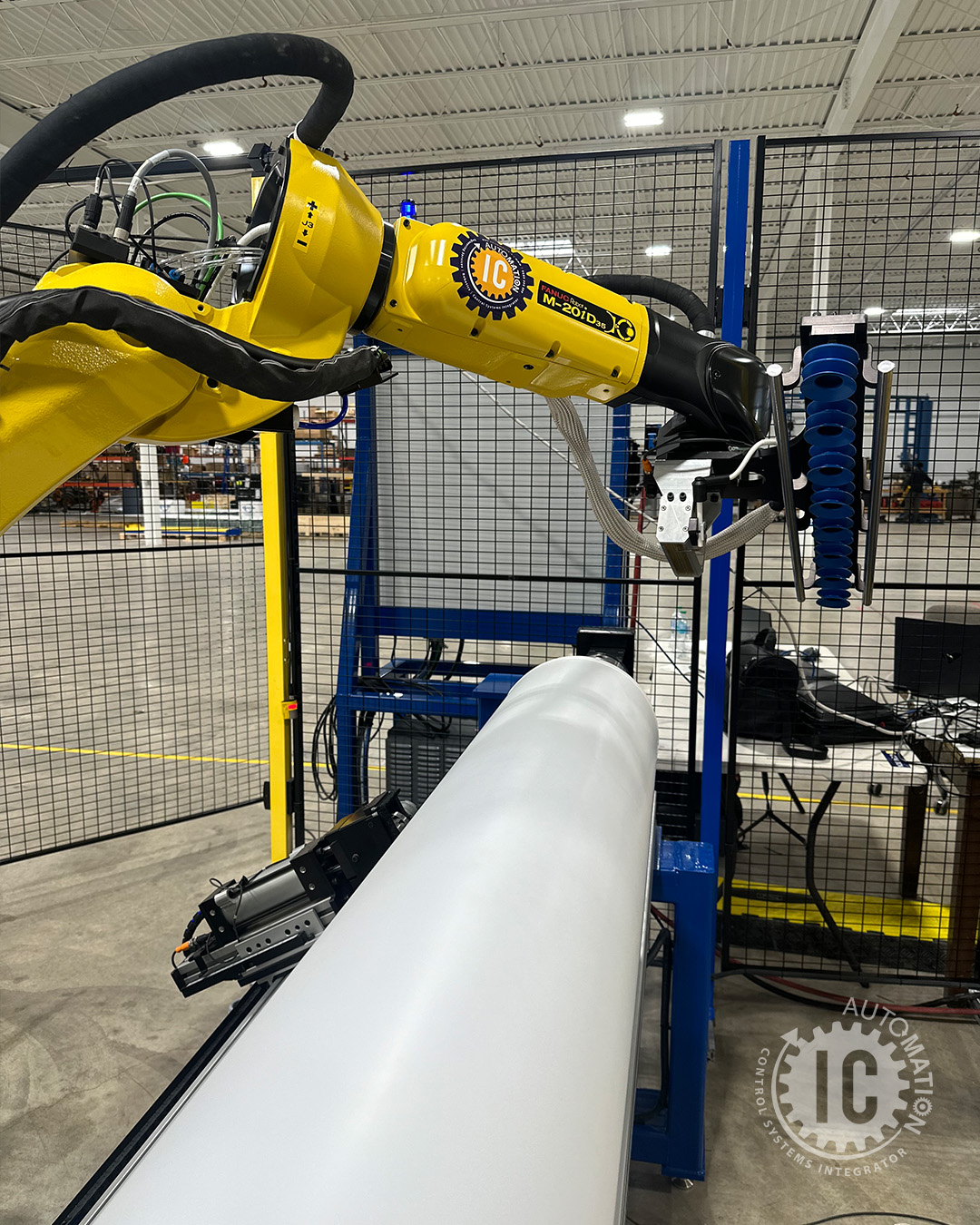

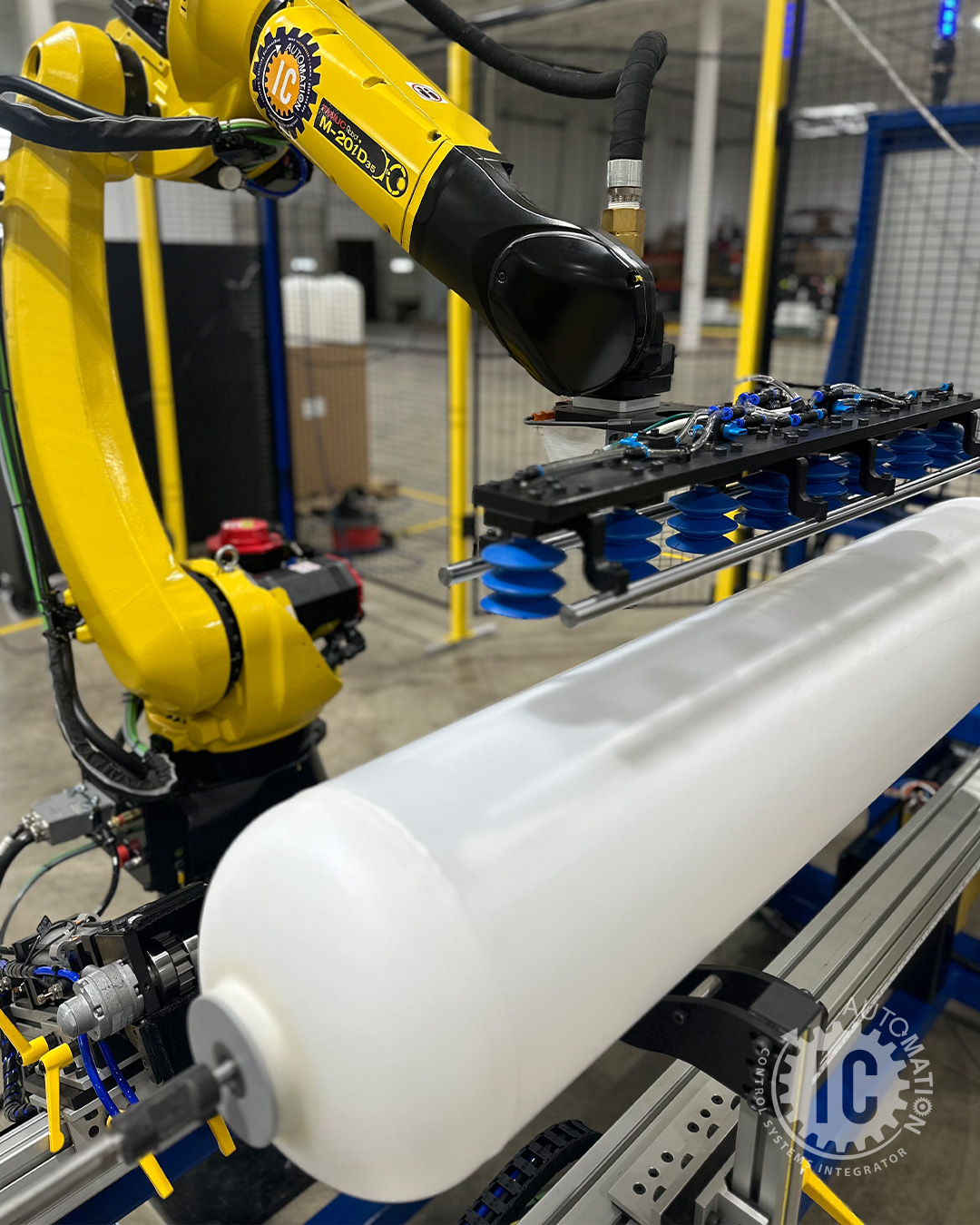

Robotic Torching System

Our custom-engineered Robotic Torching System, developed to automate the deburring and heat treatment process through advanced flame-based technology. Designed for precision and repeatability, this fully integrated workcell uses a robotic arm equipped with a specialized torch to perform surface preparation tasks with exceptional consistency and control.

By automating the traditionally manual and time-intensive process of torch-based deburring and treatment, this system significantly reduces labor requirements and improves overall part quality. Through controlled flame application, it enhances surface energy and removes burrs or contaminants, making components ready for the next step in production—whether it’s bonding, coating, or assembly.

The cell is equipped with safety features, custom fixturing, and intuitive operator controls, ensuring ease of use and reliable operation in high-volume manufacturing environments. From material handling to process control, every aspect of the system is designed to optimize throughput, minimize human error, and deliver repeatable results.

Ideal for manufacturers seeking to improve quality, consistency, and efficiency in surface preparation, this solution reflects IC Automation’s commitment to innovative, real-world automation that meets the demands of modern production.

Looking to simplify or automate your manufacturing process?

Whether you’re just exploring options or ready to take the next step, our team is here to help. We make automation approachable and tailored to your needs. Reach out today and let’s start the conversation.

Address

6441 Davis Industrial Parkway

Solon, Ohio, 44139

United States

Phone